|

|

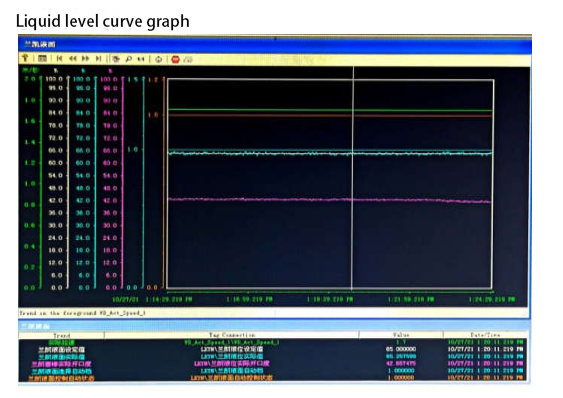

LK-EM Electromagnetic Molten Steel Level Control System |

Main Features:

●The sensor is embedded in the mold, which does not affect the replacement of the nozzle and facilitates maintenance.

●The sensor has excellent resistance to temperature drift, strong anti-interference capability, and a long service life.

●Based on the principle of electromagnetic induction, it is non-radioactive and harmless to the human body.

●Heavy-duty steel shell structure, with no damage to the sensor caused by general molten steel overflow.

●The stopper rod control system adopts a direct-drive actuator, featuring fast response.

●Electric cylinder with card slot-type quick installation, small size, light weight and good acceleration performance

●The system adopts closed-loop control, and the servo system features stable and reliable performance.

|

Main Application Fields:

It is used to detect the molten steel level in the slab mold, output the corresponding liquid level height in real time, and automatically control the molten steel level in the mold through the stopper rod system. 补充说明:

|

Main Equipment:

Electromagnetic Liquid Level Detection Host、Electromagnetic Liquid Level Sensor、Preamplifier、Servo Electric Cylinder、Servo Driver、Stopper Rod Actuator、Upper Computer (Host Computer)、Touch Screen、PLC、I/O Module、On-site Operation Box

|

| Technical Parameters |

| Model: |

LK - EM - SP - PT - □ - □ |

| Detection Range (Typical): |

20 ~ 160mm |

| Stability (Near Control Liquid Level): |

±5mm |

| Detection Accuracy (Near Control Liquid Level): |

≤±1mm |

| Control Accuracy (Near Control Liquid Level): |

≤±3mm |

| Detection Resolution: |

0.1mm |

| Electric Cylinder Movement Speed: |

80mm/s |

| Actuator Thrust: |

400kgf, Adjustable |

| No - load Reverse Thrust: |

≤15kgf |

| System Response Time: |

≤50ms |

| Electrical Parameters |

| Analog Output: |

4 - 20 mA |

| Digital Output: |

RS232 / PROFIBUS DP |

| Power Supply: |

220VAC, 380VAC |

| General Parameters |

| Sensor Material: |

Stainless Steel |

| Sensor Weight: |

Approximately 30kg |

| Sensor Operating Temperature: |

-20°C ~ +80°C |

| Sensor Protection Class: |

IP56 |

| Electric Cylinder Installation Method: |

Slot - type Quick Installation |

| Electric Cylinder Weight: |

Approximately 9kg |

| Electric Cylinder Operating Temperature : |

≤150°C |

| System Operating Humidity: |

≤90%, No Condensation |

|

|

|

|

|