|

|

LK-AR Intelligent Baking Control System for Ladles and Tundishes |

System Features:

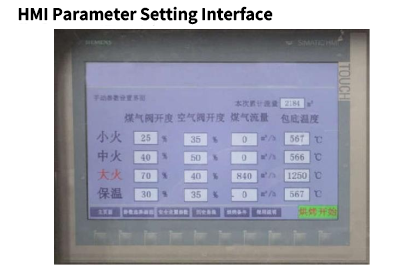

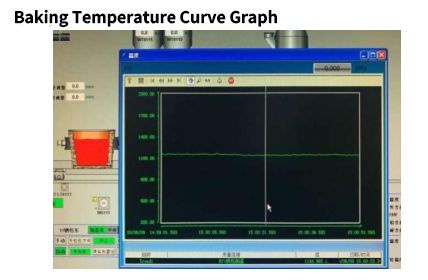

●It has multiple built-in baking model curves to realize one-button automatic baking

●The baking mode can be adjusted and optimized to prevent over-baking or under-baking

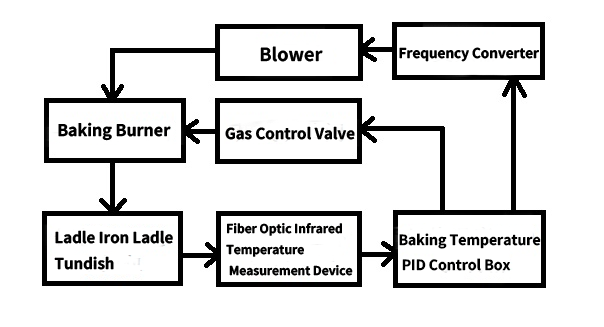

●The gas flow is automatically controlled by temperature, making it more environmentally friendly and energy-efficient

●The blower's air volume is controlled by a frequency converter to improve combustion efficiency

●The touch screen can display statuses such as baking temperature, flow rate, and pressure

●It can realize on-site data collection, storage, processing and query

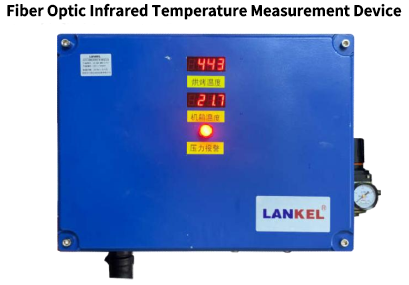

●German Original Fiber Optic Infrared Thermometer is Selected to Ensure Accurate Temperature Measurement;

●Patented Fiber Optic Infrared Temperature Measurement Device, Maintenance-Free with Fast Response

|

Main Application Fields:

It is suitable for the transformation of traditional ladle and tundish baking equipment. Only minimal modifications need to be made to the existing hardware to achieve low-cost automatic baking control.

|

System Composition:

PLC Control Cabinet、Siemens PLC、I/O Module、Communication Module、HMI Touch Screen、Fiber Optic Infrared Temperature Measurement Device、Wireless Transmission Device

|

| Performance Parameters |

| Model: |

LK-AR-MB15-F□ |

| Baking Model: |

Baking curves for large/medium/small

repaired ladles, new ladles, etc. |

| Gas Regulation: |

Manual/Automatic |

| Air Regulation: |

Manual/Automatic |

| Temperature Control Range: |

0℃~1500℃ |

| Stability: |

±5℃ |

| Detection Accuracy: |

≤±1% |

| Control Accuracy: |

≤±3% |

| Response Time: |

≤50ms |

| Electrical Parameters |

| Control Output: |

4~20mA (2 channels, expandable) |

| |

Controls control valves and frequency converters |

| Analog Output: |

4~20mA (baking temperature, flow, pressure, etc.) |

| Relay Output: |

1 channel (controls purging air source, expandable) |

| Wireless Transmission: |

All signals can be wirelessly transmitted to

the control room |

| Energy Display: |

Instantaneous flow, single-batch flow, cumulative total |

| Digital Output: |

RS485 (optional) |

| Power Supply: |

220VAC |

| General Parameters |

| Combustion Medium: |

Mixed Gas |

| Control Box Dimensions: |

800*600*250mm |

| Fiber Length: |

12m (other lengths need customization) |

| Ambient Temperature: |

-10~300℃ (infrared fiber probe) |

| |

-10~60℃ (control box) |

| Storage Temperature: |

-20~80℃ |

| Relative Humidity: |

10~90%, non-condensing |

| Environmental Rating: |

IP65 (NEMA-4) |

|

|

|

|

|