|

|

LK-FS-G Intelligent Flow Switch |

Product Features:

●Fully waterproof housing design, effectively preventing entanglements.

●Suitable for a wide range of pipe diameters, with arbitrarily adjustable setpoints.

●High-pressure type, with a pressure resistance of 60MPa.

●6 LEDs display the fluid status in real-time and can achieve the following monitoring functions: Medium flow velocity decreasing/increasing; Medium present/absent; Medium flowing/static

●Probe with anti-fouling coating, which effectively prevents the adhesion of scale, rust and other dirt in the pipeline, and has strong anti-fouling ability.

●Suitable for monitoring the flow velocity and flow interruption of fluids in pipelines, and preventing pump idling.

●Monitor the liquid flow in the pipeline in real-time and provide switch output.

|

Main Application Fields:

Petrochemical, electric power, metallurgy, steel mills, papermaking, food processing, water treatment, battery factories and other industries.

|

| Main Technical Parameters |

| Measurement range: |

Water: 0.03 - 3 m/s; Oil: 0.03 - 3 m/s; Gas: 2 - 20 m/s |

| Pressure resistance: |

4 MPa (special 60 MPa) |

| Connection method: |

Thread G1/2", G1/4", others |

| Switching time: ON: |

Typical ≥ 4s (1 - 13s); OFF: Typical ≥ 4s (1 - 15s) |

| Temperature change response time: |

≤ 12s |

| Operating voltage: |

DC24V, AC/DC220V |

| Power consumption: |

2W |

| Output: |

Relay, NPN/PNP output |

| Contact capacity: |

0.4A/125VAC, 2A/30VDC |

| Insulation resistance: |

50 MΩ at 100VDC |

| Probe material: |

304 stainless steel |

| Shell material: |

304 stainless steel |

| Operating temperature: |

-10°C - 60°C |

| Environmental conditions: |

-20 - 85°C, ≤ 85%RH |

| Protection class: |

IP67 |

|

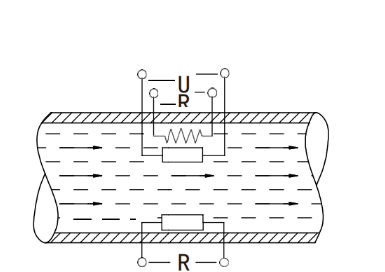

Working Principle

LK-FS-G Intelligent Flow Switch The is designed based on the principle of heat exchange. The probe has a built - in heating module and heat - sensing module. The heat transfer of the flow switch is closely related to the flow rate of the same medium. During measurement, heat is emitted by the heating module. If there is no medium flow in the pipeline, the heat received by the heat - sensing module is a fixed value; when there is medium flow, the heat received by the heat - sensing module will change with the change of the medium's flow rate. The heat - sensing module converts this temperature difference signal into an electrical signal, and then the processor converts it into a corresponding standard analog quantity signal or contact signal for output. The flow switch displays and controls the flow rate of the medium through this signal.

|

|